- CORPORATE

- CERTIFICATES

- PRODUCTS

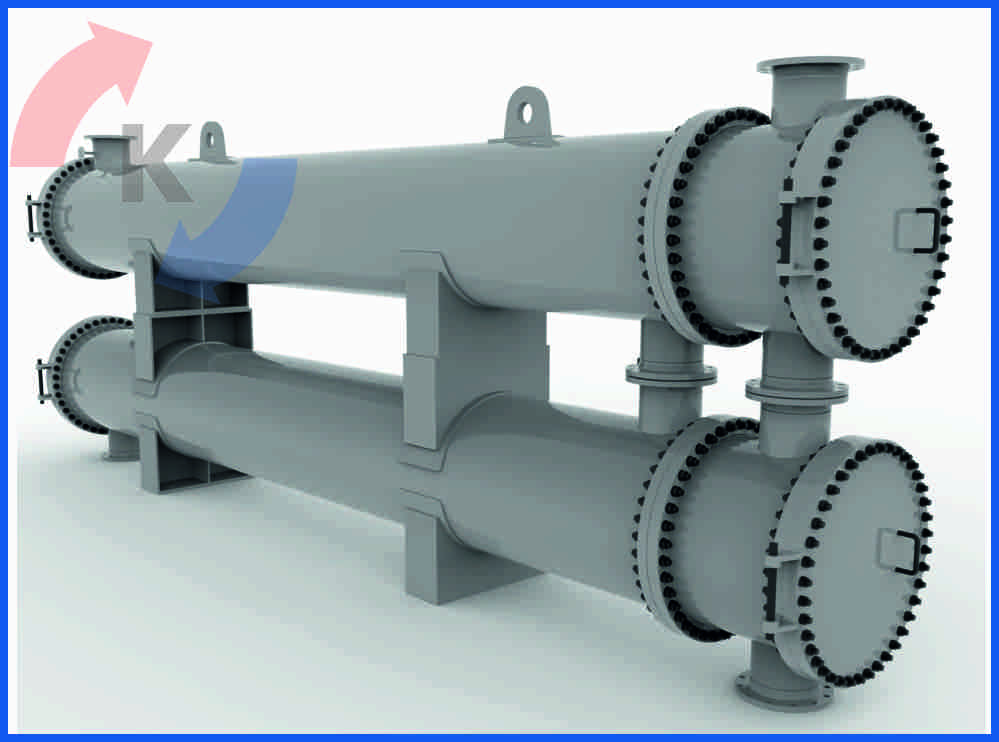

- » Shell & Tube Heat Exchangers

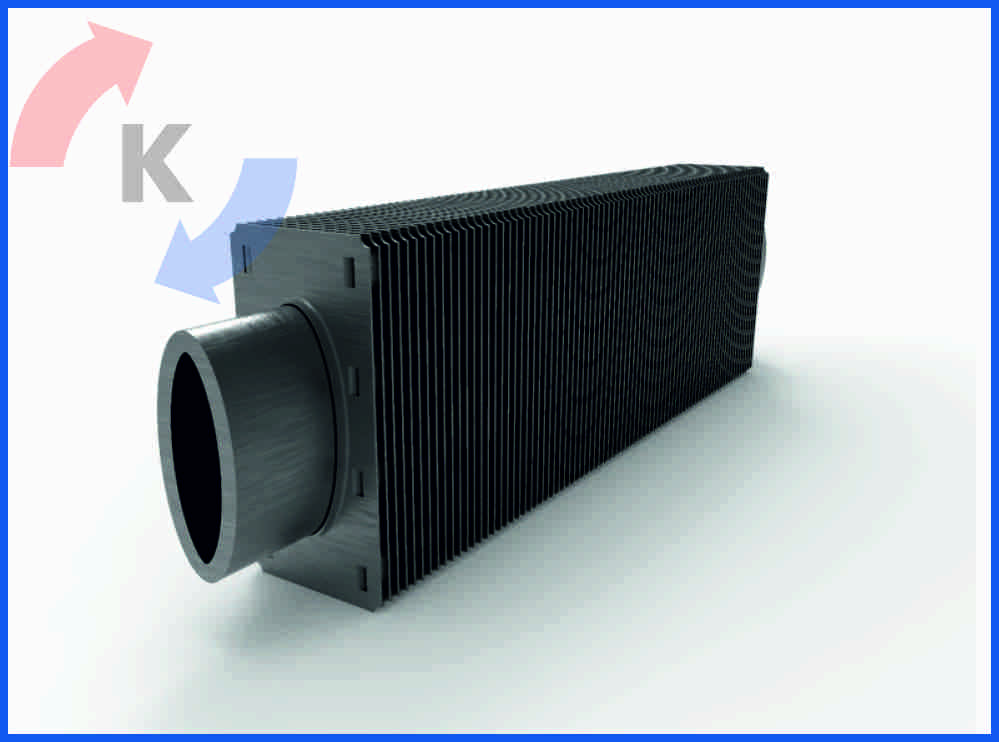

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

Size Nasıl Yardımcı OlabilirizTurnkey Cooling Towers & Pump Station

Konuk Isı designs and designs turnkey cooling towers and pumping stations with its expert engineers and technical team. The designed projects are assembled and commissioning works are carried out in the field by Konsa Energy, one of the Konuk group companies.

KONSA ENERGY was first established in 2004 within KONUK ISI to provide contracting services and in 2009, it was transformed into a separate company providing engineering, construction, installation, maintenance, project supervision and management, feasibility and consultancy services. Today, more than 35 projects have been completed and it has more than 120 permanent employees and has a structure that can create and direct a team of 300-400 people depending on the projects. Konsa ENERJİ has grown rapidly and has become a company that looks to the future with confidence due to its success in all projects carried out since the day it started its activities as a contracting group within KONUK ISI.

Catalogue

Konuk ISI’s specialist engineers and technical team design the turnkey cooling tower and pump station project. Designed projects are being done by Konuk ISI’S companies on the site assembly and commissioning works through Konsa Enerji.

Catalogue

Konuk ISI’s specialist engineers and technical team design the turnkey cooling tower and pump station project. Designed projects are being done by Konuk ISI’S companies on the site assembly and commissioning works through Konsa Enerji.

KONSA ENERJİ, first established within KONUK ISI to provide contracting services in 2004 and in 2009, has become a different company, serving especially in engineering, construction, installation, maintenance, project supervision and management, feasibility and consultancy. Today, more than 35 projects have been completed, and have more than 120 permanent employees, and has a structure to be able to support and guide a 300-400 persons team according to the projects. Because of success obtained by carried out projects since the day it began to operate as contracting group with in KONUK ISI, KONSA ENERJİ has grown rapidly and become a company facing to future with confidence.

Turnkey Cooling Towers and Pump Station project steps:

Construction, architectural, static, piping, mechanical equipment installation, electrical projects are prepared in accordance with customer requirements and technical specifications.

Once the projects have been approved, construction works begin in accordance with static and architectural projects.

Mechanical equipments such as pump, butterfly valve, plate exchanger, filter and installation of piping works begin.

Instruments such as flow meter, temperature, pressure, level are assembled.

Installation of MCC, PLC, Compensation panel is done.

Cable ties and cables are installed between the panel room and the field equipments.

Hydrostatics of the pipelines are done after the completion of the piping works.

PLC installation and automation after completing cabling works.

While the automation works are continuing, the motors and instruments in the field are supplied with electricity and tested.

After all the tests are completed, the automation tests are started.

When the whole system catches up with the automation, the facility is delivered to the customer in a ready-to-use manner.

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP