- CORPORATE

- CERTIFICATES

- PRODUCTS

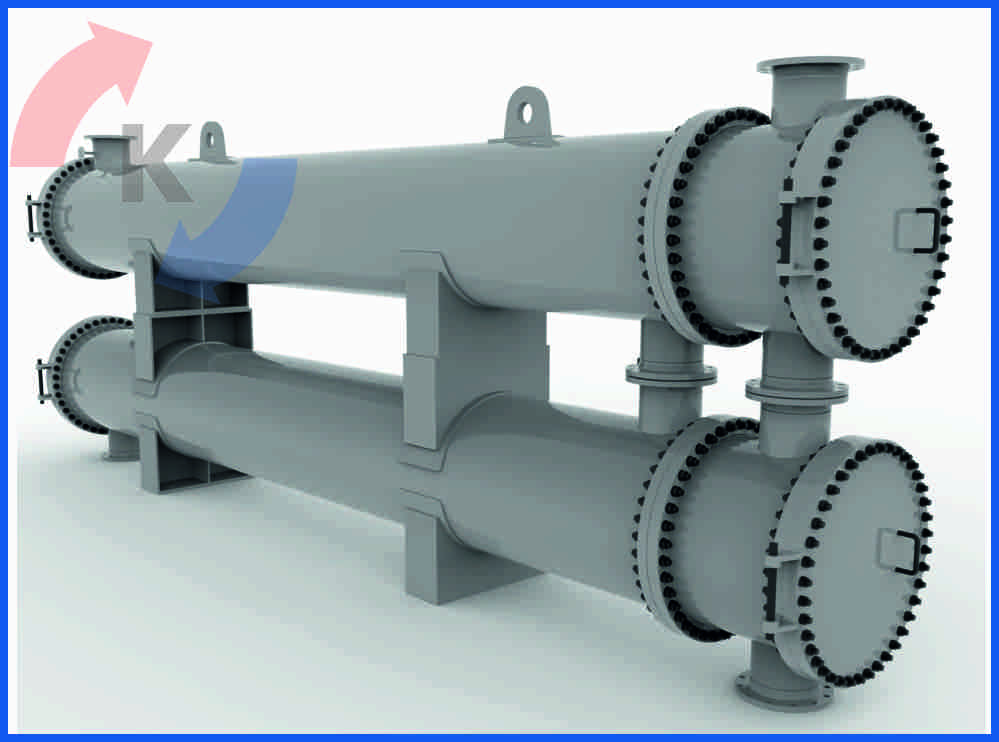

- » Shell & Tube Heat Exchangers

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

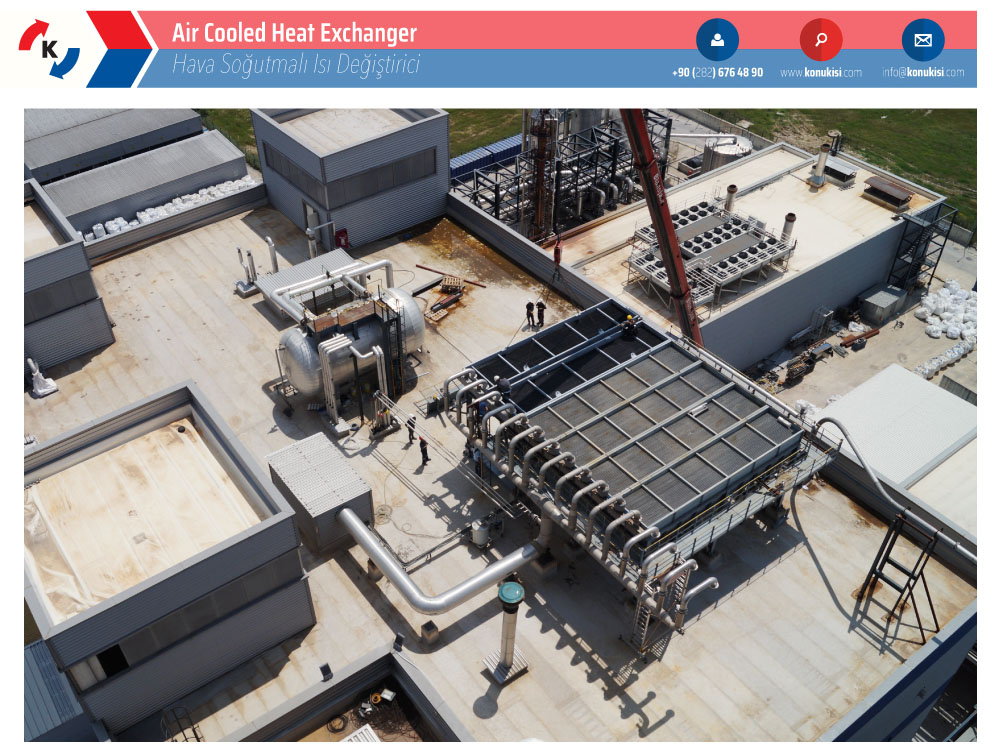

Size Nasıl Yardımcı OlabilirizAir Cooled Heat Exchangers

Konuk Isı air-cooled heat exchangers must constantly prove their quality under extreme conditions and guarantee reliable operation. For this reason, a team of specialised engineers, welding experts and other quality inspectors carefully examine and design every part and component. This process ensures that we meet all quality requirements. The main documents we have and the standards we apply are as follows.

Catalogue

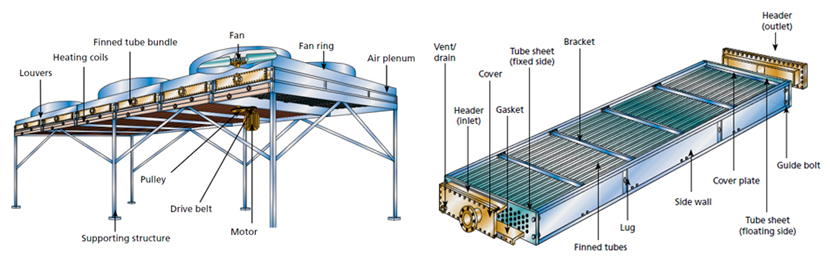

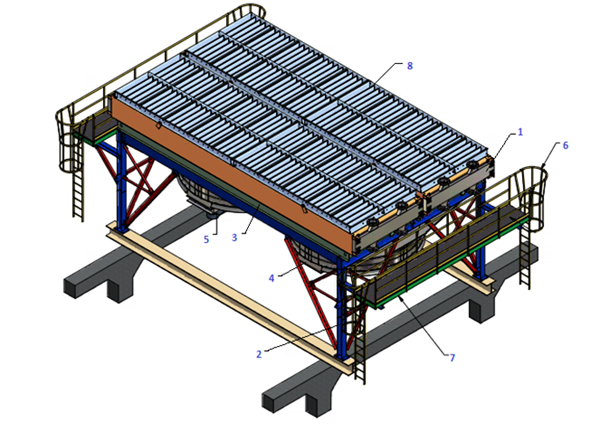

Air cooled heat exchangers are commonly used in industrial applications where a reliable source of water is not available as a cooling medium. Even if water is available, in some cases, air cooled exchangers are favored for economic or operational reasons.

Catalogue

Air cooled heat exchangers are commonly used in industrial applications where a reliable source of water is not available as a cooling medium. Even if water is available, in some cases, air cooled exchangers are favored for economic or operational reasons.

Air cooled heat exchangers are used throughout the entire oil and gas industry from upstream production to refineries and petrochemical plants, under conditions including high pressure and temperature, as well as corrosive fluids and environments.

Konuk ISI air coolers often have to prove their worth under extreme conditions and guarantee reliable operation. This is why a team of experts including engineers, welding experts and other quality inspectors scrutinizes every apparatus and every single component very precisely. This procedure ensures that we meet all quality requirements. And we achieve this in complete control as numerous certifications demonstrate. These certifications comprise both the safety requirements according to international pressure vessel regulations PED 97/23/EG, EN13445, ASME (U-Stamp) and special certificates for the Chinese (SQL) and the Russian (GOST) market.

Konuk ISI constantly underpins its technological leadership with new product developments. This includes special high-performance finned tubes with optimized material and design, enabling clearly more efficient heat exchange. This pays off for you in two ways. The investment cost is reduced and you save in operating costs. Both benefits can be achieved while enjoying high-level product reliability even under extreme conditions.

Finned tube bundles with aluminium fins are considerably lighter, are insensitive to soiling and easy to clean. On the other hand, systems using galvanized steel offer a very long service life of up to 30 years, are extremely resistant to mechanical influences such as hailstorms and provide optimum corrosion protection as aluminium.

Air coolers are used in fundamentally different and sometimes extremely difficult ambient conditions. This refers to both production processes and climate-related conditions. What is needed are designs that are up to these requirements at any time, while also taking the customers’ wishes into account.

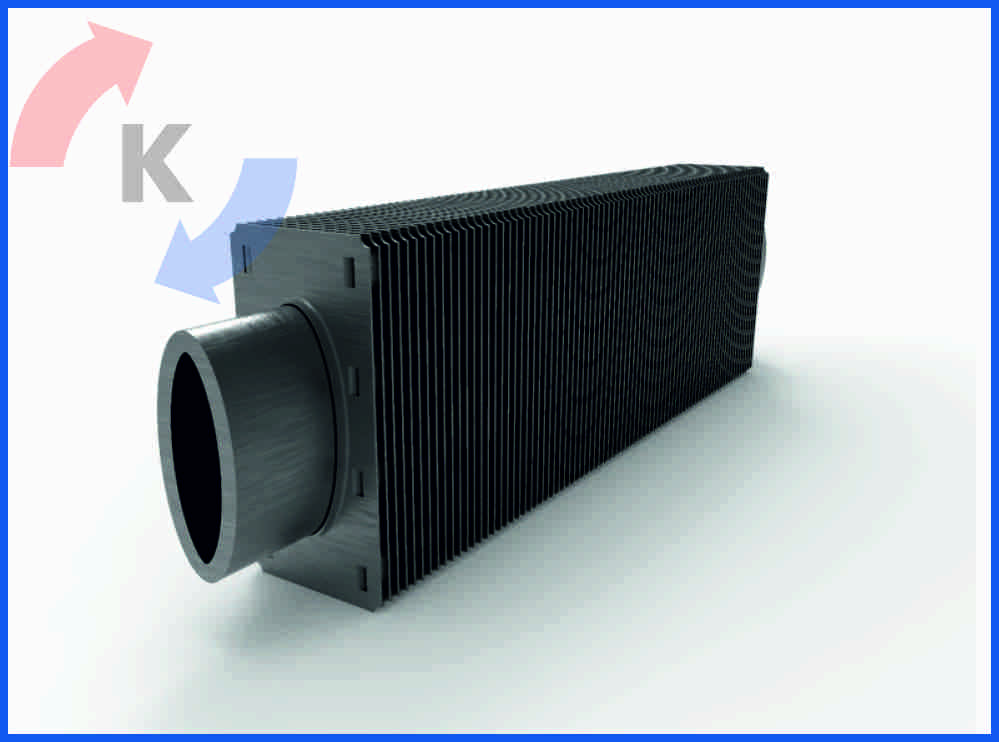

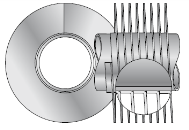

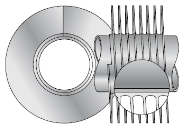

A finned tube bundle consists of finned tubes (in special cases unfinned tubes are also possible), the headers for distributing the product and a supporting frame.

L-FIN B-FIN G-FIN

L-FIN

Tubes with L-fins (or knurled L-fins) are used in environments with moderate requirements for the mechanical and thermal stability. During fabrication a fin-strip of aluminium is preformed into an L-shape and then wound onto the tube under tension.

Material fin: Aluminium

Material core tube: Any metallic material

Max. operating termperature: 150 °C

B-FIN ( Extruded )

Tubes with extruded aluminium fins have a high mechanical and thermal stability. The fin is extruded from an aluminium tube that is slid onto the core tube. That creates a strong bond between tube and fin with excellent heat conduction properties.

Material fin: aluminium

Material core tube: any metallic material

Max. operating termperature: 300 °C

G-FIN

Tubes with embedded fins have very good heat conduction properties and a high thermal stability. The mechanical stability varies with the choice of fin material. The fin is spirally wound into a groove in the tube and tightly bonded to it by rolling.

Material fin: aluminium, carbon steel

Material core tube: carbon steel, stainless steel

Max. operating termperature: 400 °C

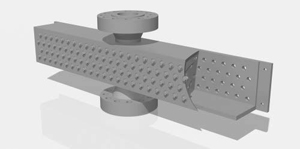

Welded Bonnet Header

Here a bonnet header is welded to the tubesheet. The process nozzles are located on the bonnet. This header design is suitable for processes where no access the tubes or tubeto-tubesheet connection is required. The maximum design pressure is approximately 100 bar.

Here a bonnet header is welded to the tubesheet. The process nozzles are located on the bonnet. This header design is suitable for processes where no access the tubes or tubeto-tubesheet connection is required. The maximum design pressure is approximately 100 bar.

Removable Cover Plate

The header frame and the tubesheet form a box. The cover plate is mounted to the header box with a bolted flange connection. This design allows the removal of the cover plate for cleaning and maintenance purposes. The process nozzles can be located on the header frame or the cover plate. The maximum design pressure is approximately 50 bar. If higher design pressures are required special designs can be used.

The header frame and the tubesheet form a box. The cover plate is mounted to the header box with a bolted flange connection. This design allows the removal of the cover plate for cleaning and maintenance purposes. The process nozzles can be located on the header frame or the cover plate. The maximum design pressure is approximately 50 bar. If higher design pressures are required special designs can be used.

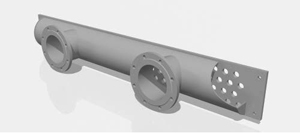

Plug header

A plug header is a fully welded box header. Opposite of every heat exchanger tube a removable plug is installed in the plugsheet for cleaning and maintenance purposes. This header design can be used for high pressure applications up to approximately 250 bar.

A plug header is a fully welded box header. Opposite of every heat exchanger tube a removable plug is installed in the plugsheet for cleaning and maintenance purposes. This header design can be used for high pressure applications up to approximately 250 bar.

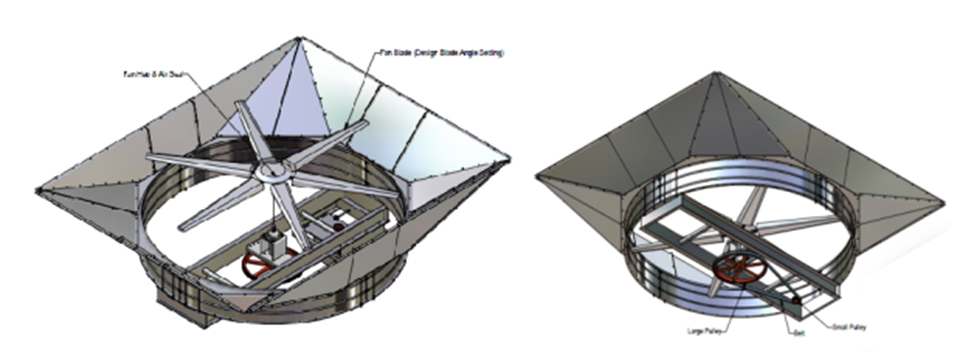

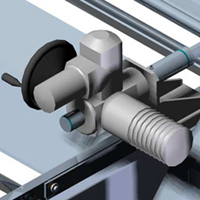

The cooling air that is required for the cooling process is moved through the heat exchanger bundles by axial fans. The design of the fans and the selection of the fan type is based on the particular design point given by the heat exchanger design. Main criteria are the required volume flow of air, the pressure loss and the individual requirements regarding noise emissions.

The main components of an axial cooling fan are the fan ring, the fan impeller and the v-belt drive unit. Depending on the particular design requirements different blade profiles made of aluminium or glass fiber reinforced plastic (GRP) are used for the fan impellers. For the fan rings we are using a construction with an ellipsoid shape at the inlet side. This shape minimizes turbulence resulting in high energy efficiency and therefore reduced required power. Additionally noise emissions are optimized. The material for the fan rings is steel. For corrosion protection all parts are hot-dip galvanized. Alternatively painting or a combination of galvanizing and painting are possible.

The main components of an axial cooling fan are the fan ring, the fan impeller and the v-belt drive unit. Depending on the particular design requirements different blade profiles made of aluminium or glass fiber reinforced plastic (GRP) are used for the fan impellers. For the fan rings we are using a construction with an ellipsoid shape at the inlet side. This shape minimizes turbulence resulting in high energy efficiency and therefore reduced required power. Additionally noise emissions are optimized. The material for the fan rings is steel. For corrosion protection all parts are hot-dip galvanized. Alternatively painting or a combination of galvanizing and painting are possible.

» Fan Stack

» Fan Blade

» Fan Bearing

» V-belt drive

» Drive Motor

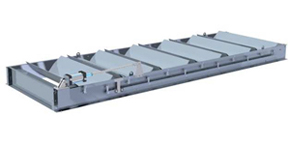

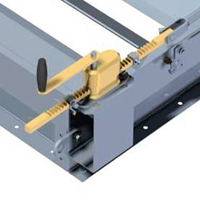

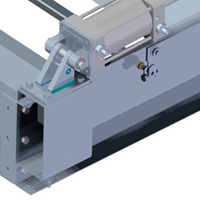

In most cases a gaseous medium (air) is led through a heat exchanger. Konuk ISI’s louvres control the quantity of medium flowing through the system. A louver consists of a number of moveable slats fixed in a frame. An operating strip on one side of the louvre couples the slats together. All slats move simultaneously.

In most cases a gaseous medium (air) is led through a heat exchanger. Konuk ISI’s louvres control the quantity of medium flowing through the system. A louver consists of a number of moveable slats fixed in a frame. An operating strip on one side of the louvre couples the slats together. All slats move simultaneously.

Konuk ISI’s louvres can be separated into the following main groups:

» Automatic Operation

» Manual Operation

» Electrical Operation

» Pneumatic Operation

Manual Operation Electrical Operation Pneumatic Operation

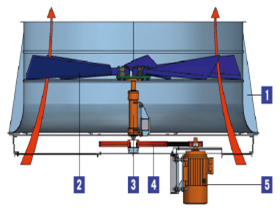

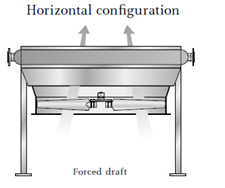

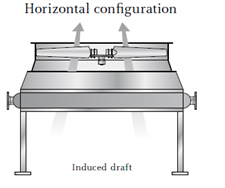

The horizontal arrangement of the heat exchanger bundles with forced draught fans underneath the bundles is the most common configuration of air cooled heat exchangers. It gives easy access to the fans and fan drives for maintenance purposes.

Induced draught arrangement of the fans above the heat exchanger bundles results in an even distribution of the cooling air to the heat exchanger surface. The plenum shades the heat exchanger surface and therefore protects it from solar radiation.

Air cooled heat exchangers in A-frame configuration are used when the plot area is restricted. The fans are arranged in forced draught.

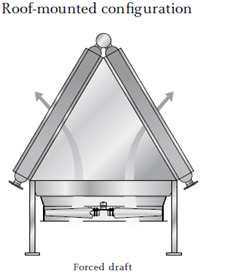

1. Steam Coils

2. Main Construction

3. Heat exchanger bundle

4. Fan Stack

5. Drive Motor

6. Access Ladder

7. Maintenance Platform

8. Louver

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP