- CORPORATE

- CERTIFICATES

- PRODUCTS

- » Shell & Tube Heat Exchangers

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

Size Nasıl Yardımcı OlabilirizShell & Tube Condensers

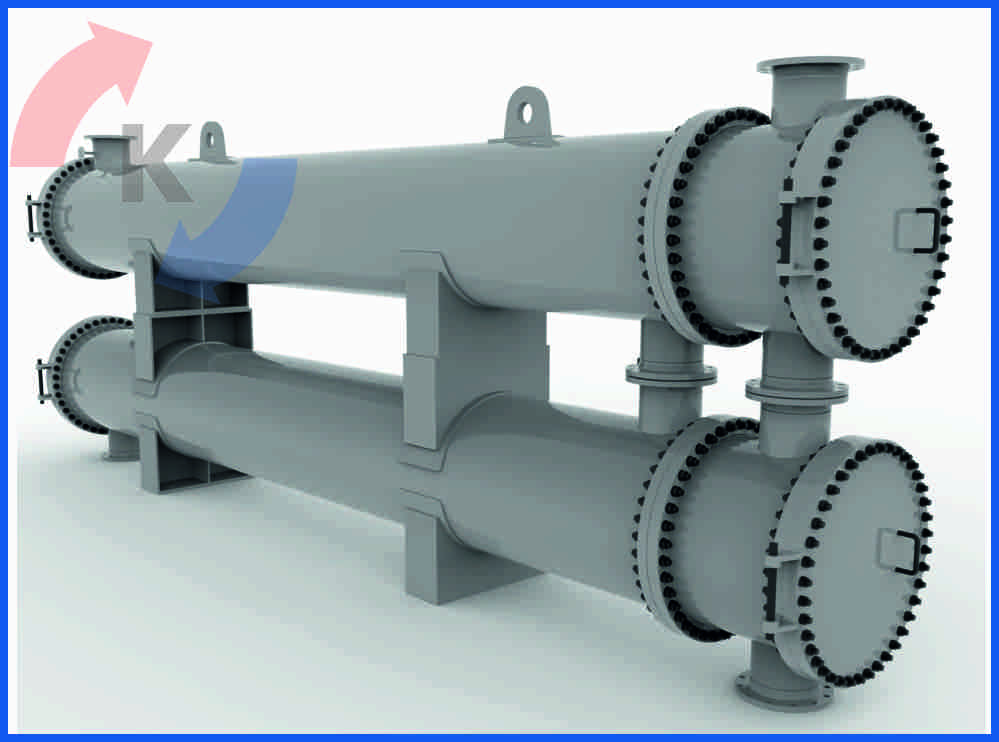

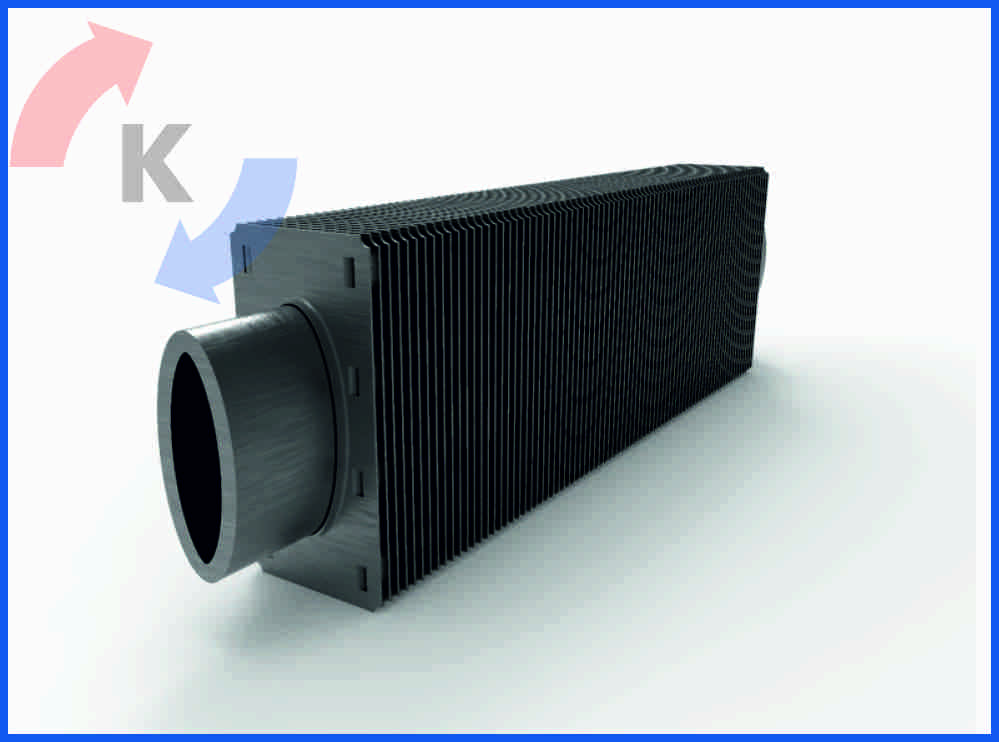

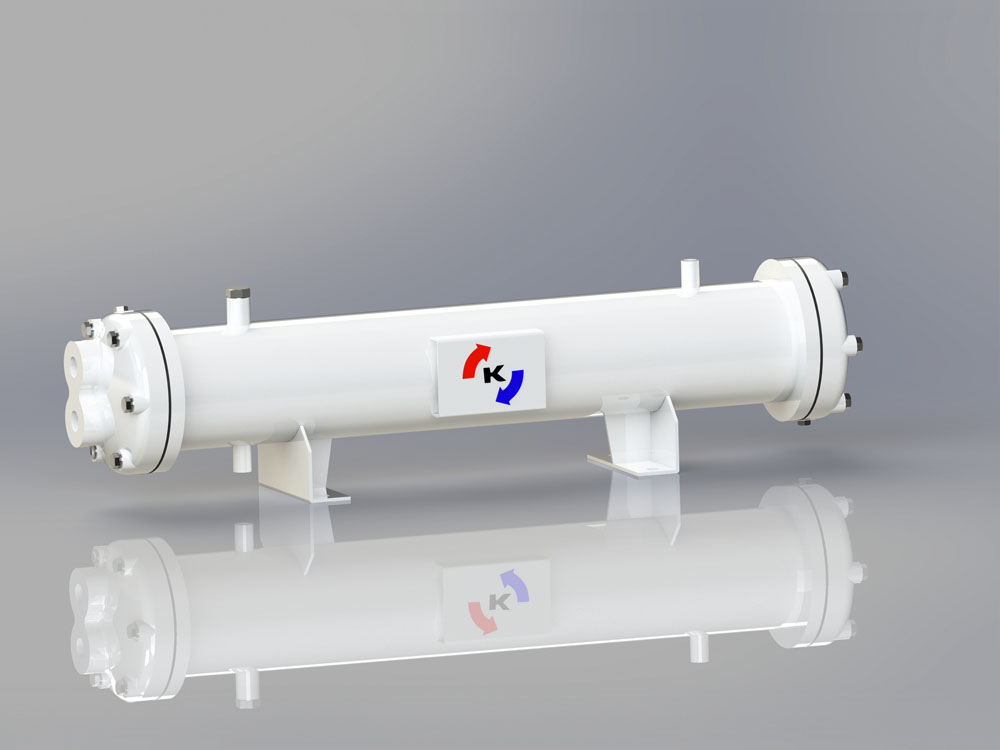

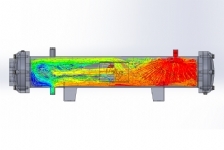

As in all heat exchangers, there are two critical elements of shell & tube condensers which are generally used for condensation of the refrigerants:

» High heating capacity

» Low pressure loss

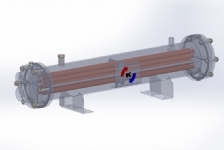

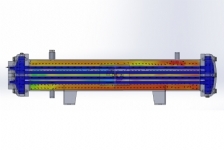

Taking into account these two basic factors, KONUK ISI has designed KK Series shell and tube condensers. Special copper tubes with increased surface condensation areas are used for products in this series. Under our licensed program, we offer several condenser tube options with different surface and geometric characteristics. In our condensers, cast shutters and special copper tubes with high condensation and heat transfer areas are used and a compact and modular design is applied with a monolithic cast of heads and legs where unions are invisible.

The materials used in production are carefully chosen in accordance with safety requirements taking into account operating pressure levels. Moreover, our condensers have safety valves for protection against high levels of working pressures. In addition to that safety valve, shell-tube condensers have a service valve, gas inlet and fluid outlet located over the main body. The products are cleaned before installation. Catalogue

As in all heat exchangers, there are two critical elements of shell & tube condensers which are generally used for condensation of the refrigerants:

Catalogue

As in all heat exchangers, there are two critical elements of shell & tube condensers which are generally used for condensation of the refrigerants:

» High heating capacity

» Low pressure loss

Taking into account these two basic factors, KONUK ISI has designed KK Series shell and tube condensers. Special copper tubes with increased surface condensation areas are used for products in this series. Under our licensed program, we offer several condenser tube options with different surface and geometric characteristics. In our condensers, cast shutters and special copper tubes with high condensation and heat transfer areas are used and a compact and modular design is applied with a monolithic cast of heads and legs where unions are invisible.

The materials used in production are carefully chosen in accordance with safety requirements taking into account operating pressure levels. Moreover, our condensers have safety valves for protection against high levels of working pressures. In addition to that safety valve, shell-tube condensers have a service valve, gas inlet and fluid outlet located over the main body. The products are cleaned before installation.

For sea water applications, it is necessary to apply designs which are appropriate for sea water corrosion conditions. Since there will be changes in values such as fouling factor, working conditions and the materials and geometrics of shutters and tubes etc, it would be advisable to get into contact with our company in such a situation. To achieve the best performance, longest possible service life without any problem, Design and Production of our condensers are based on the following principles:

» Appropriateness of the design from a thermal and mechanical perspective ,

» Convenience of assembly and maintenance for the system where the product will be used,

» High Material Quality

» Selection of most accurate methods of production and provision of appropriate conditions for production.

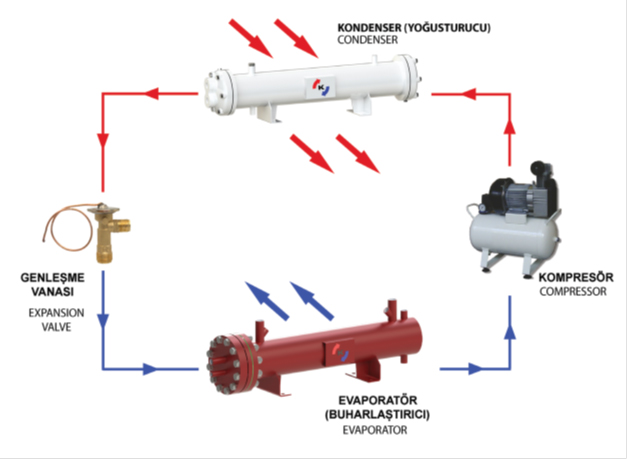

Soğutma çevrimi, ısıyı emen soğutucu akışkanın sonrasında yayması sonucu oluşan ısı değişiklikleri olarak tanımlanabilir. Bu ısı değişiklikleri bir soğutucu içinde gerçekleşir. Çevrim döngüsü şu şekilde ifade edilebilir:

Alçak basınçtaki soğutucu akışkan kompresör tarafından yüksek basınca çıkartıldıktan sonra kondensere yollanır. Kondenserde yoğuşma oluşturularak genleşme valfine yollanır ve burdan geçirilerek alçak basınçlı sıvı haline dönüştürülür. Buradan da evaporatör vasıtası ile soğutma gerçekleştirilir.

Soğutma Çevrimi Şeması:

» Kondenser (Yoğuşturucu)

» Genleşme Vanası (Kısılma Vanası)

» Evaporatör (Buharlaştırıcı)

» Kompresör

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP