- CORPORATE

- CERTIFICATES

- PRODUCTS

- » Shell & Tube Heat Exchangers

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

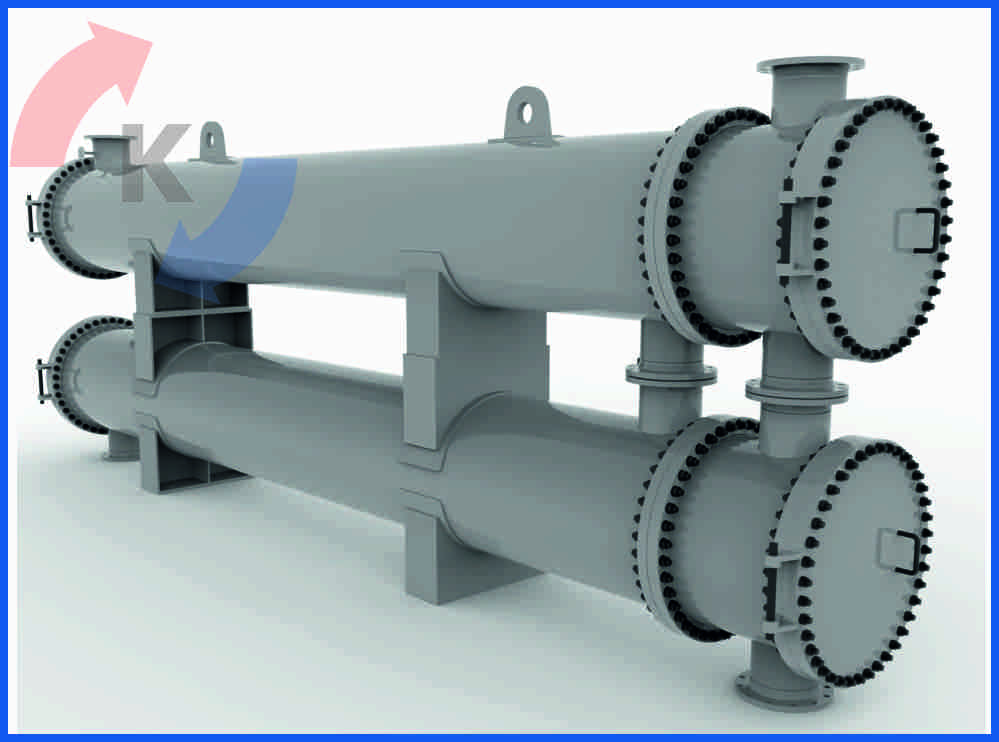

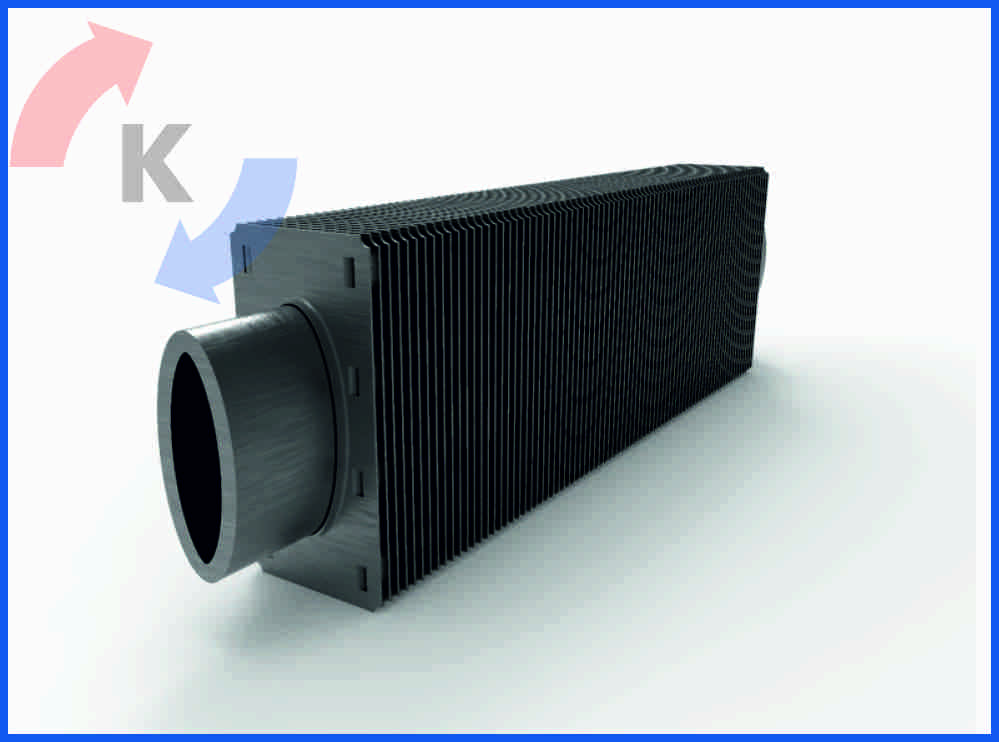

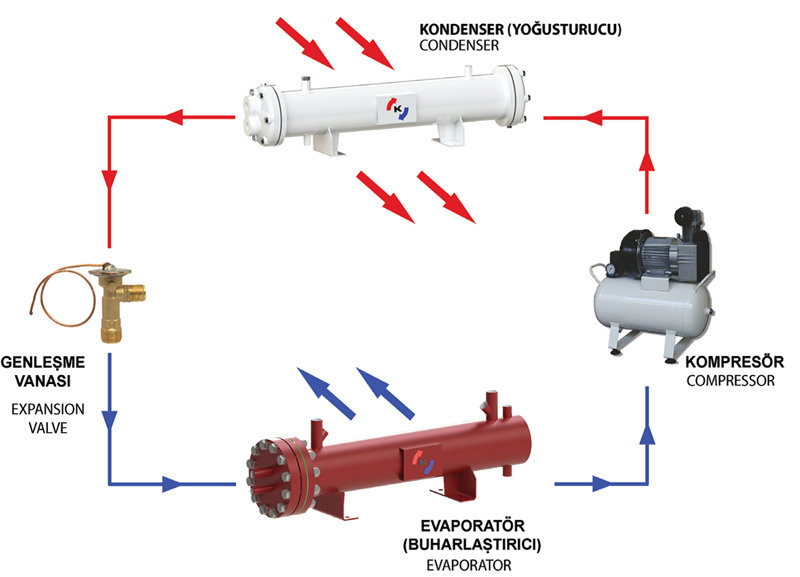

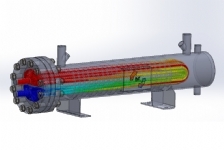

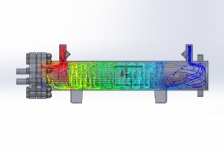

Size Nasıl Yardımcı OlabilirizShell & Tube Evaporators

KONUK ISI has been continuing its activities with a wide product range targeting heating and cooling sector, under the principle “We are present wherever there is a demand for heat exchange”. As it always gives priority to the customers ’ satisfaction, KONUK ISI has initiated the production of standard shell & tube evaporators with a view to meeting demands received from its customers.

There are 36 options available for KONUK ISI evaporators based on capacity and geometry. They are produced with single or double cooling circuits. The capacity range of the evaporators varies between 9 kW and 875 kW for conditions specified. All HFC and HCFC are appropriate as refrigerant fluids. Tube bundle is detachable. This enables maintenance and cleaning. Please get into contact with our company for your special orders not existing in the catalogue. Shell & Tube Evaporators

KONUK ISI has been continuing its activities with a wide product range targeting heating and cooling sector, under the principle “We are present wherever there is a demand for heat exchange”. As it always gives priority to the customers ’ satisfaction, KONUK ISI has initiated the production of standard shell & tube evaporators with a view to meeting demands received from its customers.

Shell & Tube Evaporators

KONUK ISI has been continuing its activities with a wide product range targeting heating and cooling sector, under the principle “We are present wherever there is a demand for heat exchange”. As it always gives priority to the customers ’ satisfaction, KONUK ISI has initiated the production of standard shell & tube evaporators with a view to meeting demands received from its customers.

There are 36 options available for KONUK ISI evaporators based on capacity and geometry. They are produced with single or double cooling circuits. The capacity range of the evaporators varies between 9 kW and 875 kW for conditions specified. All HFC and HCFC are appropriate as refrigerant fluids. Tube bundle is detachable. This enables maintenance and cleaning. Please get into contact with our company for your special orders not existing in the catalogue.

To achieve the best performance, longest possible service life without any problem, design and production of our evaporators are based on the following:

» Appropriateness of the design from a thermal and mechanical perspective ,

» Convenience of assembly and maintenance for the system where the product will be used,

» High material quality

» Selection of most accurate methods of production and provision of appropriate conditions for production.

For sea water applications, it is necessary to apply designs which are appropriate for sea water corrosion conditions. Since there will be changes in values such as fouling factor, working conditions and the materials and geometrics of shutters and tubes etc, it would be advisable to get into contact with our company in such a situation.

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP