- CORPORATE

- CERTIFICATES

- PRODUCTS

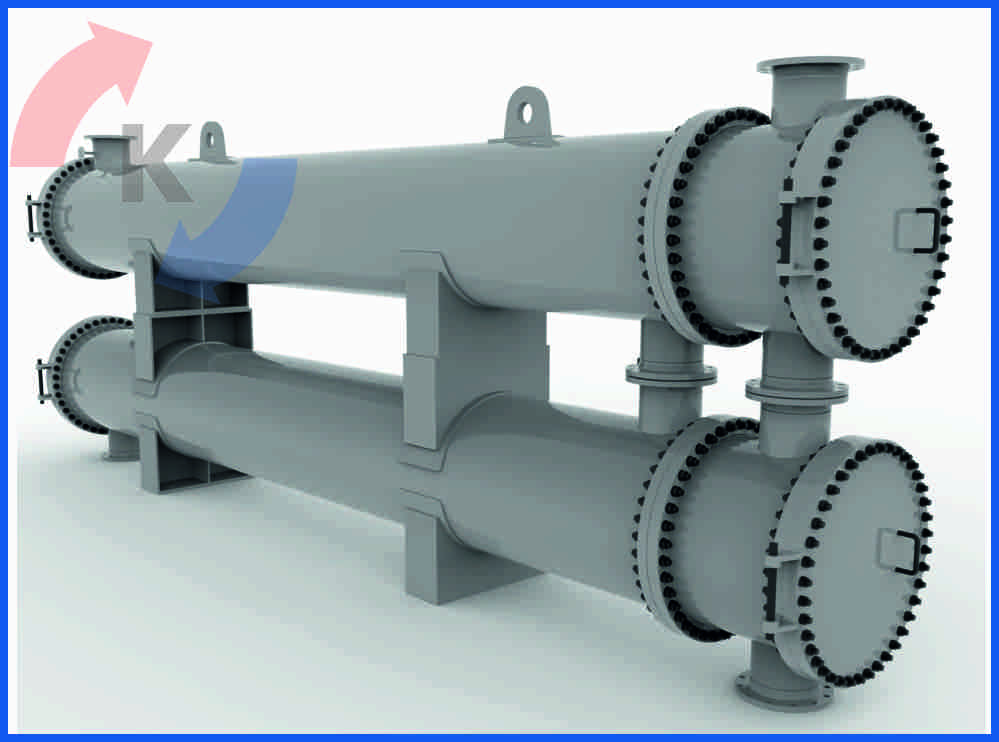

- » Shell & Tube Heat Exchangers

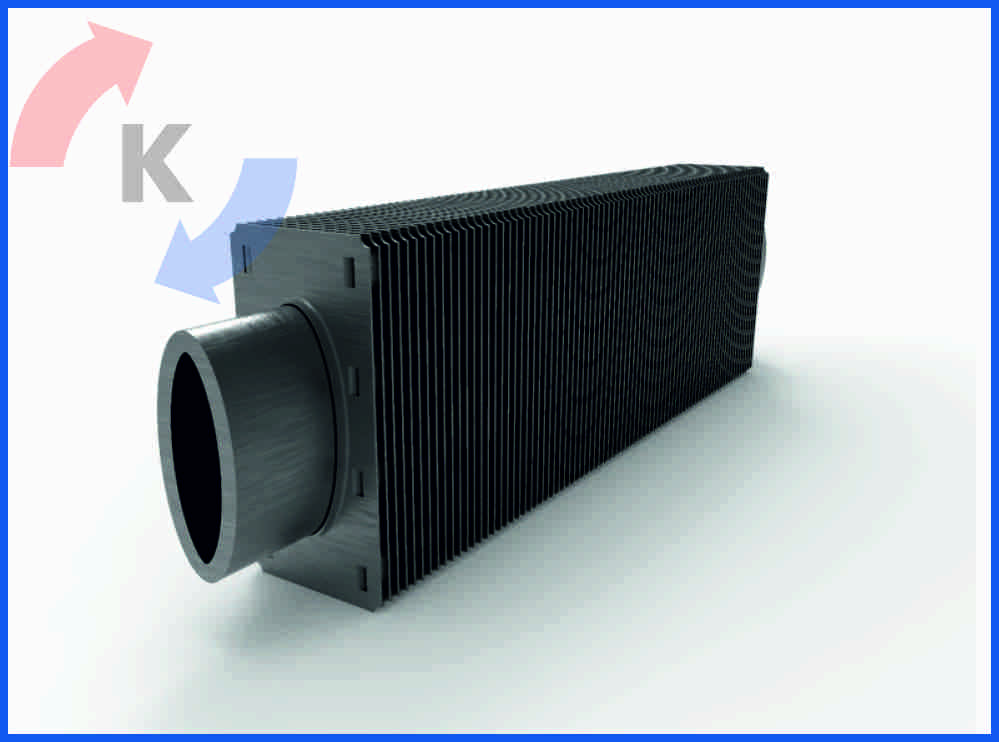

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

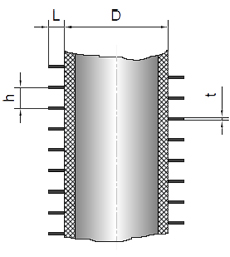

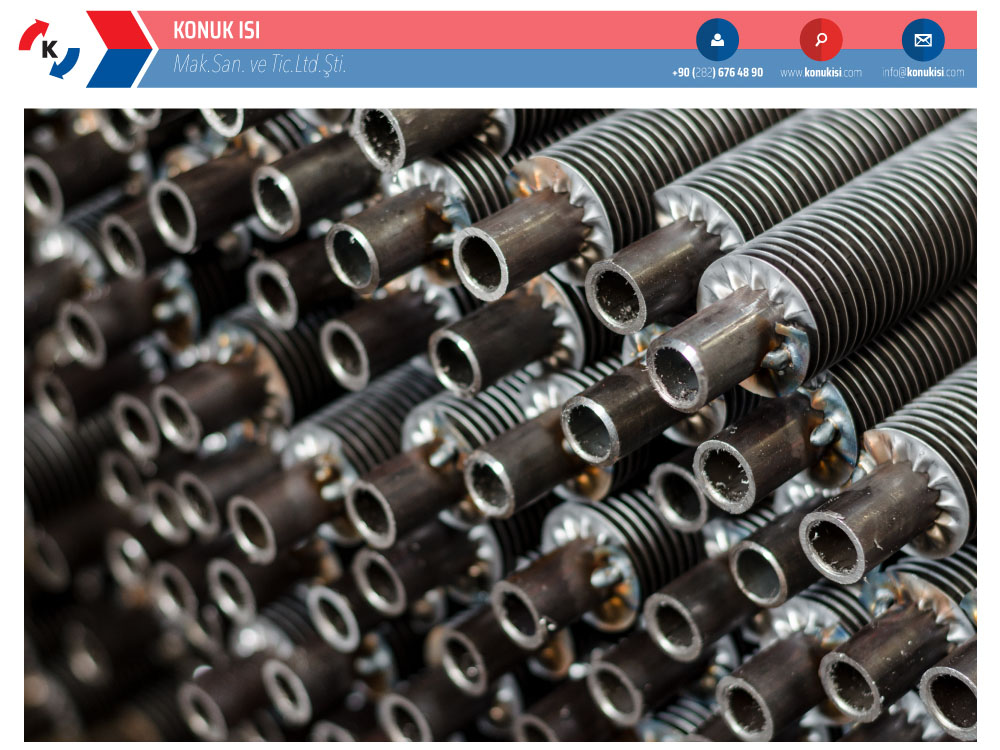

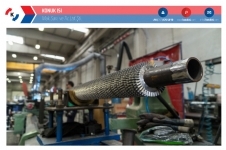

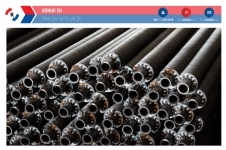

Size Nasıl Yardımcı OlabilirizSpiral Finned Serpentines

Depending on the customer's requirements, the serpentines are manufactured by applying an electro-galvanised or hot-dip galvanised coating to the DKP finned serpentine types made of carbon steel tubes.

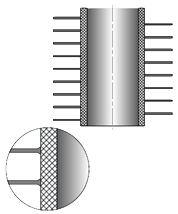

This coating increases heat transfer and reduces oxidation in serpentine production. In standard serpentine products, the fins are attached to the tube by spot welding. However, depending on the customer's requirements, continuous welding between the fin and the tube can also be used in serpentine production.

Catalogue

Catalogue

According to customer demands, electro galvanize or hot-dip galvanize coating can be applied to carbon steel tube-St2 finned serpentine types; tin or solder coating can be applied to copper and copper alloyed tubecopper finned serpentine types. With the help of these coatings oxidation is decreased whereas heat transfer is increased.

According to customer demands, electro galvanize or hot-dip galvanize coating can be applied to carbon steel tube-St2 finned serpentine types; tin or solder coating can be applied to copper and copper alloyed tubecopper finned serpentine types. With the help of these coatings oxidation is decreased whereas heat transfer is increased.

Main use areas of serpentines can be summarized like this:

» Air heaters for textile machines,

» Air heaters for drying machines,

» Air heaters for air handling units

» Air coolers

» Turbo charge coolers

» Oil coolers

» Water coolers

» Air coolers for vessels

Spiral finned serpentine types which we produce are classified according to production methods:

» Standard spot welded serpentines

» Continuous welded serpentines

» High frequency welded serpentines

» G finned tubes

» L finned tubes

Tube Diameter (D) Pitch(h) Fin Height (L) Fin Thickness (t) Ø 6-9 2.5-6.5 5.0-10 0,4 Ø 9-12 2.5-6.5 5.0-10 0,4 Ø 12-16 2.5-6.5 5.0-12 0,4 Ø 16-21 2.5-6.5 5.0-12 0,4 Ø 21-27 2.5-4.5 5.0-10 0,4 3.0-8.0 10-16 0,40-1-1,2 Ø 27-34 2.5-5.0 5.0-10 0,4 3.0-10 10-20 0,40-1-1,2 Ø 34-43 2.5-6.0 5.0-a10 0,4 4.0-20 8.0-25 0,40-1-1,2 Ø 43-120 2.5-6.0 5.0-10 0,4 4.0-6.5 8.0-16 0,40-1-1,2 7.0-28 10-30 0,40-1-1,2

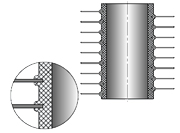

Continuous Welded Serpentines

Bu tip serpantinlerde boru ve kanat birbirine, tam teması sağlamak için, MIG kaynak yöntemi ile tutturulur. Kaynak işleminin uygulanabilmesi için kanat kalınlığının en az 1 mm olması gerekir.

Boru ve kanat birbirine kaynakla birleştirilmiş olduğu için bu şekilde üretilen serpantinler, punta kaynaklı serpantinlere göre çok daha yüksek sıcaklıklarda kullanılabilir.

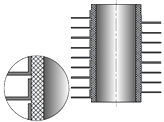

High Frequency Welded Serpentines

High frequency welded serpentines are the most special type among spiral finned serpentines. These serpentines have especially high heat resistance, because their minimum fin thickness is 0.8mm. For high frequency welded serpentines, high frequency electric energy is applied to fin and tube, which creates compete fusion and penetration between the tube and the fin. With complete contact created with this welding process, serpentine’s heat transfer and mechanical resistance increases and fin-tube form is maintained even at high temperatures.

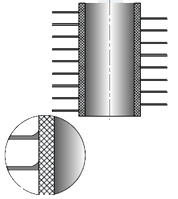

G-Fin:

Fin is mechanically embedded in a grove to the tube surface and wrapped. Maximum working heat is 400°C. It is produced with carbon steel, Cr-Mo steel, stainless steel, copper and copper alloyed tubes, copper and aluminum fin material.

L-Fin:

L shaped fin is wrapped by being stretched on tube. Maximum working heat is 150℃. It is produced with all tube types and copper and aluminum fin material.

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP