- CORPORATE

- CERTIFICATES

- PRODUCTS

- » Shell & Tube Heat Exchangers

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

Size Nasıl Yardımcı OlabilirizIntegral Finned Serpentines

Integral Finned Serpentines (Extruded Tubes)

Broşür

For this type of serpentines, fins are created with direct tube by using extrusion method. It provides the best heat transfer, because there is no resistance between tube and fin. Integral finned tubes are classified as follows:

Broşür

For this type of serpentines, fins are created with direct tube by using extrusion method. It provides the best heat transfer, because there is no resistance between tube and fin. Integral finned tubes are classified as follows:

» Integral finned serpentines with single tube

» Integral finned serpentines with double tube

» Corrugated and integral finned tubes

» Turbofin tubes

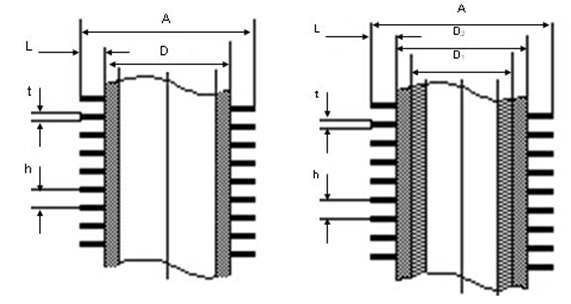

Integral Finned Serpentines With Single Tube:

They are produced by using soft tubes of materials such as copper and aluminum with below sizes:

Tube Diameter (D) : D 15-25mm (before extrusion)

Fin Height (L) : L 2-5 mm

Fin Thickness (t) : t 0.20-0.40 mm

Pitch (h) : h 1.33-3.20 mm

Integral Finned Serpentines With Double Tube:

Best heat transfer surface area is obtained by using integral finned serpentines. But this method could not be directly applied with hard materials such as carbon steel, stainless, bafon and brass. To apply extrusion method for these types of tube, a soft tube such as copper or aluminum is placed on them and fin is formed with that outer tube with below sizes:

Inner Tube Diameter (D1) : 10-33.70 mm

Fin Height (L) : 5-15 mm

Fin Thickness (t) : 0.20-0.40 mm

Pitch (h) : 2-3.20 mm

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP