- CORPORATE

- CERTIFICATES

- PRODUCTS

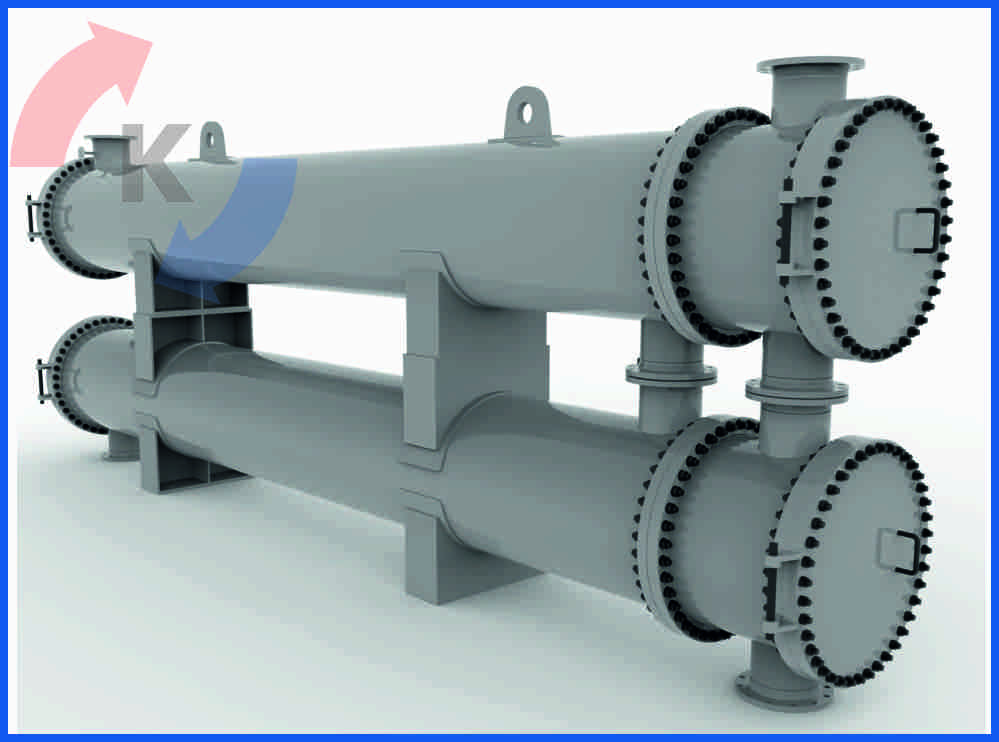

- » Shell & Tube Heat Exchangers

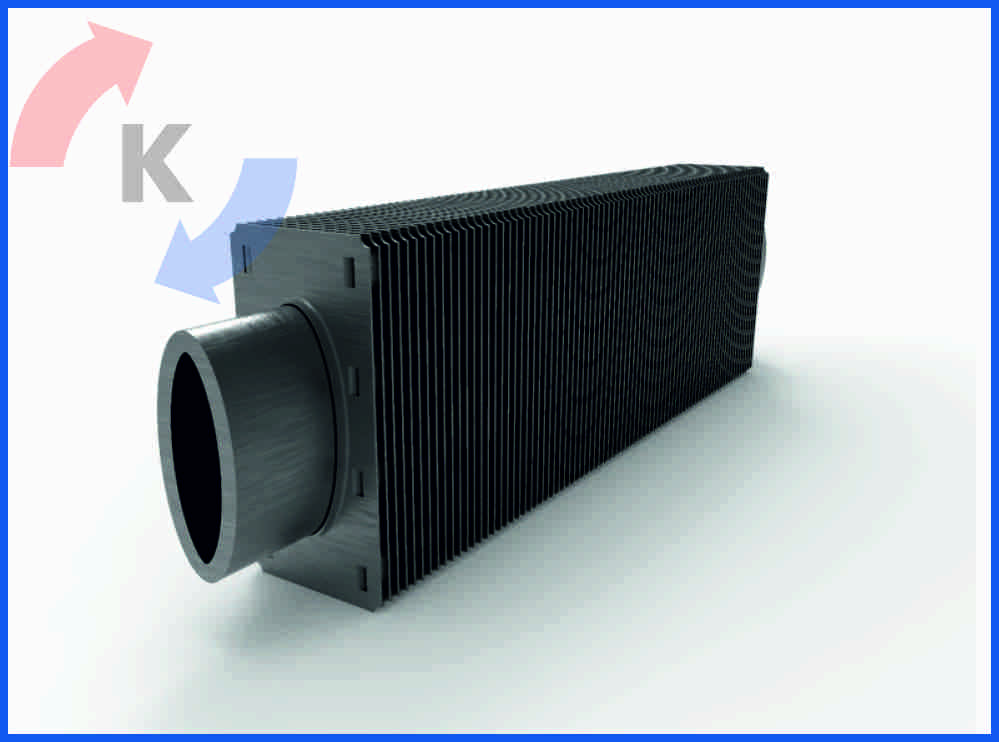

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

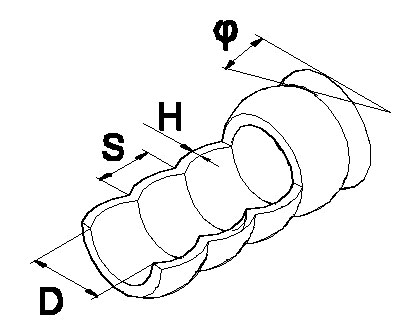

Size Nasıl Yardımcı OlabilirizCorrugated and Integral Finned Tubes

At heat exchangers, fluid property, flow state and heat transfer surface area are important for heat transfer and pressure reduction. The surface shape of corrugated tubes increases the turbulence of the fluid. The flow patterns which are forced spirally around the tubes, is provides a turbulence even at low flow speeds and heat transfer rate is able to be increased significantly. Grooving the tubes with a spiral pattern does not create a negative effect on material strength; on the contrary, it generates the property of improved thermal expansion.

Corrugated tubes are generally used for evaporator or condenser type heat exchangers for cooling and air-conditioning purposes. Also, the heat exchangers which are produced with this type of tubes are suitable for industrial usage such as air pump, condenser/chiller, waste gas, steam, water, glycol, alcohol, oil and many other applications. Corrugated tubes can be applied on heat exchangers as long as environment’s pollution tendency allows. The external contact surface of the integral tubes is increased approximately 2.5-3 times compared with smooth tubes.

Ortamın kirlenme eğilimi izin verdiği sürece ısı değiştiricilerinde kroçilli borular kullanılabilir. Tasarım hesaplamalarında kroçilli borular düz borularla karşılaştırıldığında ısı transferinin daha iyi olduğu görülmektedir. Kroçilli borulardaki akışta, ısı iletim katsayısı h, sürtünme çarpanı f ve basınç düşümü ΔP, deneysel yöntemlere dayalı veriler kullanılarak hesaplanır.

d: İç çap

s: Hatve

φ: Büküm açısı

h: Oluk derinliği

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

Broşür

Broşür BACK TO TOP

BACK TO TOP