- CORPORATE

- CERTIFICATES

- PRODUCTS

- » Shell & Tube Heat Exchangers

- » Air Cooled Heat Exchangers

- » Serpentines

- » Cooling Towers

- » Shell & Tube Condensers

- » Shell & Tube Evaporators

- » Pressure Vessels

- » Radiators

- » Air Charge Cooler

- » Economizer

- » Water-Oil Heat Exchangers

- » Unit Heaters

- » Spiral Boiler Tubes

- » Plate Heat Exchangers

- » Condensers & Evaporators

- » Direct Contact Steam Condenser (Reboiler)

- » Generator Cooler With Water Cooler

- » Generator Cooler With Air Cooler

- » Compressor Cooler

- » Air Preheater

- » Recirculation Coolers

- » Charge Air Coolers

- » Exhaust Gas Heat Exchanger

- » Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CORPORATE

- CERTIFICATES

- PRODUCTS

- Shell & Tube Heat Exchangers

- Air Cooled Heat Exchangers

- Serpentines

- Cooling Towers

- Shell & Tube Condensers

- Shell & Tube Evaporators

- Pressure Vessels

- Radiators

- Air Charge Cooler

- Economizer

- Water-Oil Heat Exchangers

- Unit Heaters

- Spiral Boiler Tubes

- Plate Heat Exchangers

- Condensers & Evaporators

- Direct Contact Steam Condenser (Reboiler)

- Generator Cooler With Water Cooler

- Generator Cooler With Air Cooler

- Compressor Cooler

- Air Preheater

- Recirculation Coolers

- Charge Air Coolers

- Exhaust Gas Heat Exchanger

- Transformer Oil Coolers

- SECTORS - APPLICATIONS

- MEDIA

- CONTACT

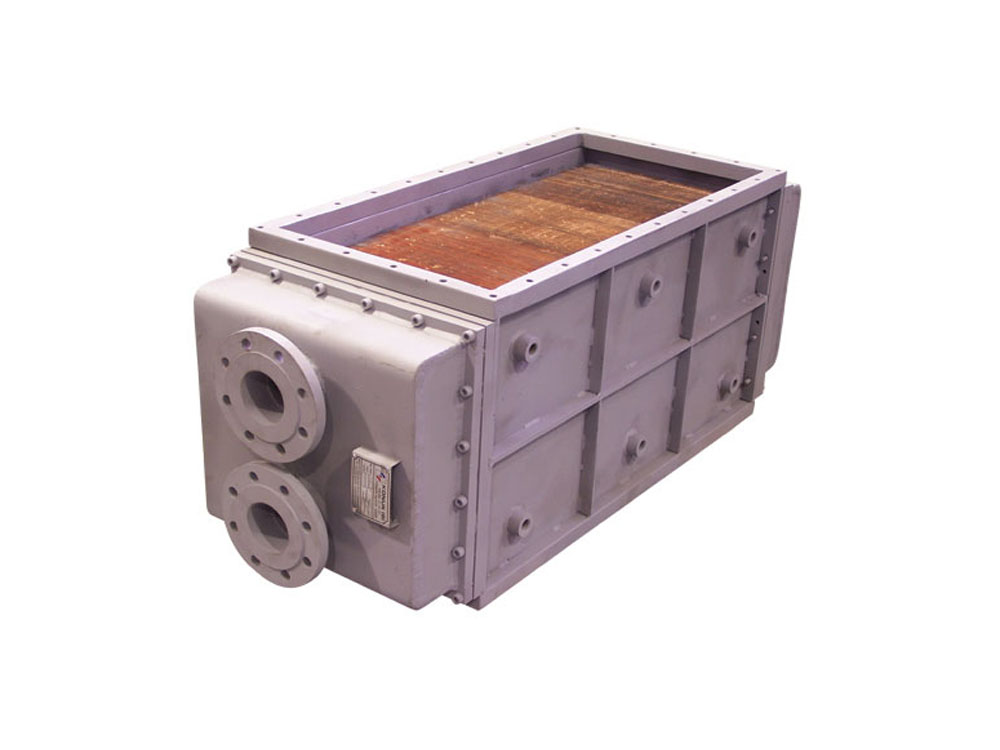

Size Nasıl Yardımcı OlabilirizRadiators

Coils are types of heat exchangers used to transfers the heat obtain from the fluid passing through the tubes, to the environment and called as radiators.

Such heat exchangers are produced by grouping finned tubes or tubes without fin, to be used with purposes such as heating, cooling, and drying.

Spiral finned serpentines or stamped-rectangular finned serpentines as well as the lamellar units prepared with special moulds will be used in radiators.

Our company engaged in the production about types of heat exchangers since 1987, has the convenient production capacity to provide every kind of project and technical specifications requested by customers. As a partner, our experienced engineering team will inspect your site to prepare your special project and to realize special designs.

For our customers, we are offering the optimum solutions, considering all factors such as the product purpose, system fluid, environment where it will be used, required capacity for radiator design, and the results of calculation which are made with special programs.Coils are types of heat exchangers used to transfers the heat obtain from the fluid passing through the tubes, to the environment and called as radiators.

Such heat exchangers are produced by grouping finned tubes or tubes without fin, to be used with purposes such as heating, cooling, and drying.

Spiral finned serpentines or stamped-rectangular finned serpentines as well as the lamellar units prepared with special moulds will be used in radiators.

Our company engaged in the production about types of heat exchangers since 1987, has the convenient production capacity to provide every kind of project and technical specifications requested by customers. As a partner, our experienced engineering team will inspect your site to prepare your special project and to realize special designs.

For our customers, we are offering the optimum solutions, considering all factors such as the product purpose, system fluid, environment where it will be used, required capacity for radiator design, and the results of calculation which are made with special programs.

While designing the project, the material types, radiator’s working conditions and environmental corrosion conditions are considered. The type of the collector, which provides fluid cycle passing through the heater tubes, is determined by considering system conditions such as fluid type, working pressure and working temperature. Fluid cycle can be provided either by tube sheets and a suitable collector covers, such as “U” type cover, triangular cover or spherical cover, or by tubes used as collector or by elbows circuiting the heater tubes. Besides, the tube-sheets & collector cover connected by welding, it is possible to combine tube-sheets & collector covers by using bolts. Such detachable collector covers are especially preferred to remove any possible acquaintance, especially for oil radiators. For tube-sheet & collector cover applications, fluid velocity is provided by appropriate baffling system to provide maximum heat transfer.

According to material type, the tubes and tube-sheets are joined either by welding or tube expanding or welding + light tube expanding.

Fin shapes of serpentines which will be used for radiator are chosen by considering system conditions, pressure drop and efficiency. Detailed information related with fin types, explained in serpentine section.

PRODUCTShell & Tube Heat Exchangers Air Cooled Heat Exchangers Serpentines Cooling Towers Shell & Tube Condensers Shell & Tube Evaporators Pressure Vessels Radiators Air Charge Cooler Economizer Water-Oil Heat Exchangers Unit Heaters Spiral Boiler Tubes Plate Heat Exchangers Condensers & Evaporators Direct Contact Steam Condenser (Reboiler) Generator Cooler With Water Cooler Generator Cooler With Air Cooler Compressor Cooler Air Preheater Recirculation Coolers Charge Air Coolers Exhaust Gas Heat Exchanger Transformer Oil CoolersCONTACT USVelimeşe Mah. Sultan Sok. No:1 Ergene / Tekirdağ

+90 282 676 48 90

+90 533 928 18 25

+90 282 676 48 98

info@konukisi.com

Konuk Isı Mak. San. ve Tic. Ltd. Şti. © 2023 Tüm Hakları Saklıdır.

+90 282 676 48 90

+90 282 676 48 90

BACK TO TOP

BACK TO TOP